Partnership from the initial stages of development

For the last 15 years, KWx has supplied system integrator Bakker Sliedrecht with products and solutions for electrical installations aboard some of the world’s most technologically advanced offshore and dredging vessels.

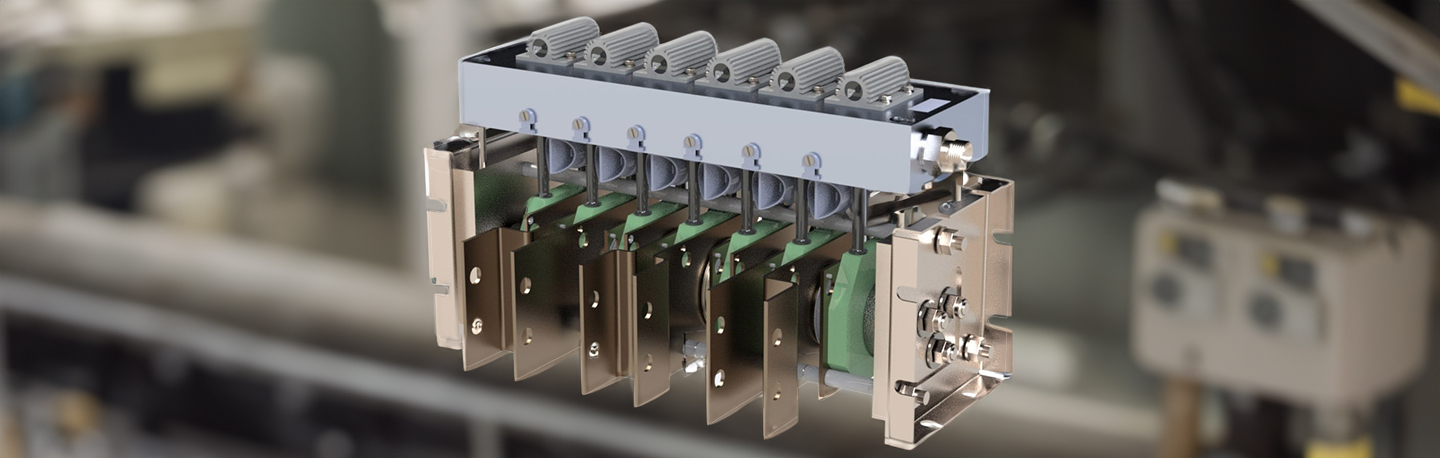

Bakker Sliedrecht designs, installs and maintains complex electrical installations. They have a proven track record in the maritime and offshore industry. For one of its projects, Bakker Sliedrecht approached KWx during the initial stages of the development. This resulted in a close collaboration for selecting a water-cooled rectifier for the drives. Besides, KWx also supplied Bakker Sliedrecht with high speed fuses.

A partner that understands the dynamics of the offshore industry

Looking back on this partnership, Arend van der Velde, manager Electronics & Machine Department at Bakker Sliedrecht, says the main benefit of partnering with KWx is the technical expertise of the team. He appreciates the close relationship KWx has established with its manufacturers and its customers

Van der Velde continues: “What is important for us is a partner that understands the dynamics of the offshore industry. In case challenges arise, KWx acknowledges the urgency our industry is characterized by and has demonstrated to act accordingly. Especially during the stage the system is put into operation, this proactive attitude is of essential importance.”

Together we improve and move onward

Currently, Bakker Sliedrecht is working on the integrated electrical installation for several new vessels. These vessels will be deployed in pipelaying, dredging and the construction of wind farms, and are scheduled to be delivered the coming years. For these vessels, KWx supplied a next generation water-cooled rectifier for the drives. During the development of this new concept, Van der Velde was very satisfied with the willingness and flexibility of the KWx team to help Bakker Sliedrecht improve and move onward.

He explains: “The new concept rectifiers allows us to build cabinets that are easier to install and to service. Which saves us time. Moreover, these rectifiers are more compact. This has allowed us to decrease the width of the cabinets from 800 millimeters to 600 millimeters. Aboard vessels, where space is always an issue, this is a big improvement.”