Rectifiers from Littelfuse

Rectifiers are electrical devices used to convert alternating current (AC) into direct current (DC). They are commonly used in power supply systems to provide a steady DC voltage for various applications. Rectifiers can be categorized into two main types based on their cooling methods: liquid-cooled rectifiers and air-cooled rectifiers.

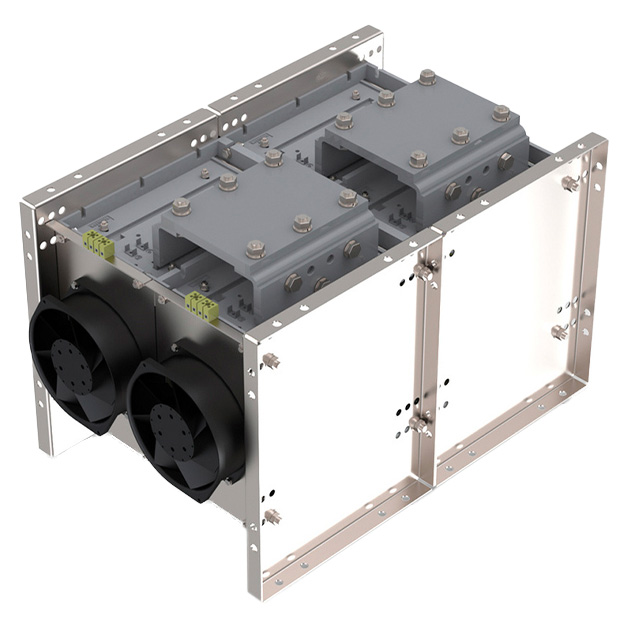

Liquid-Cooled Rectifiers

Liquid-cooled rectifiers utilize a cooling system that involves circulating a liquid coolant, such as water or oil, to dissipate heat generated during the rectification process. The rectifier components, such as diodes and transformers, are typically immersed or in direct contact with the coolant. The coolant absorbs the heat and carries it away from the rectifier, maintaining a suitable operating temperature.

Liquid cooling is commonly applied in high-power rectifier systems where the heat dissipation requirements are significant. The high thermal conductivity of liquids enables efficient heat transfer, allowing the rectifier to handle large power loads. Liquid cooling is often found in industrial applications.

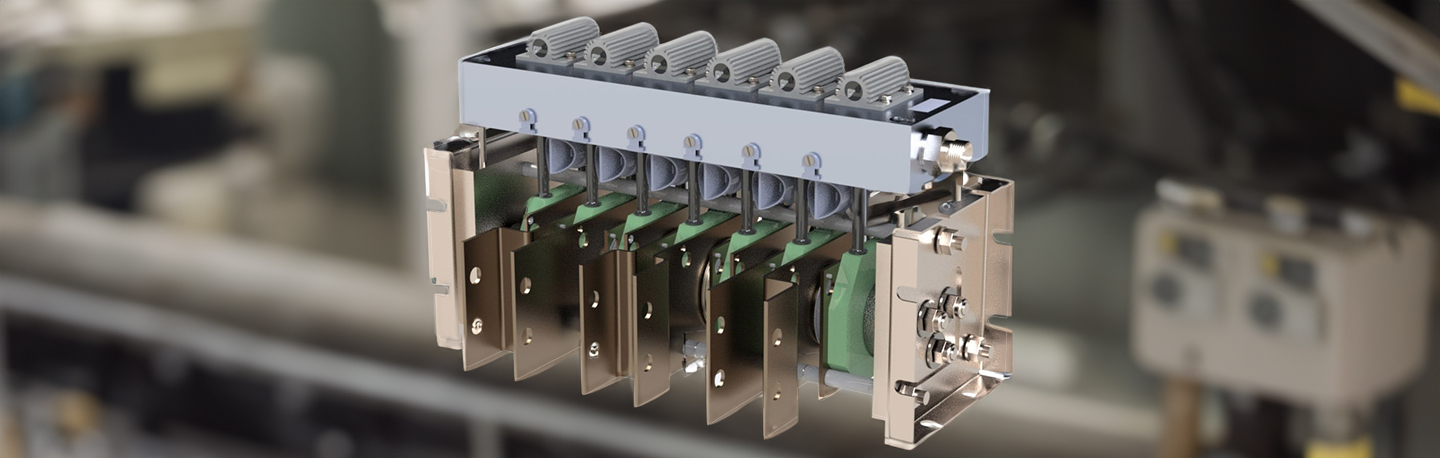

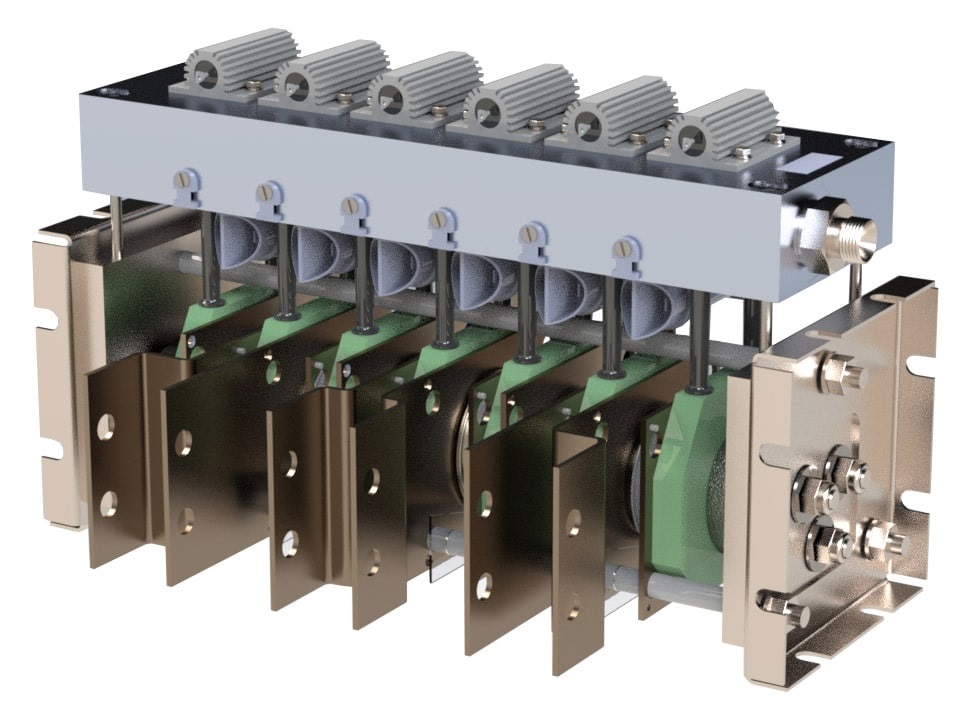

Air-Cooled Rectifiers

Air-cooled rectifiers, on the other hand, rely on the surrounding air for heat dissipation. They utilize cooling fins or heat sinks attached to the rectifier components to increase the surface area and enhance airflow. As the rectifier operates, the heat generated is transferred to the fins, and the circulating air carries away the heat, keeping the rectifier within acceptable temperature limits.

Air cooling is typically employed in lower-power rectifier applications, where the heat dissipation requirements are relatively lower. It is commonly used in consumer electronics, small-scale power supplies, and low to medium power industrial applications.

Choosing the right cooling type

The choice between liquid cooling and air cooling depends on several factors, including the power rating, operating conditions, and cost considerations. Liquid cooling is favored when dealing with high-power rectifiers that generate significant amounts of heat, as it provides better cooling efficiency. However, it requires additional infrastructure, such as coolant circulation systems and maintenance, which can increase the overall cost. Air cooling, on the other hand, is more cost-effective and simpler to implement but may have limitations in dissipating heat for high-power applications.