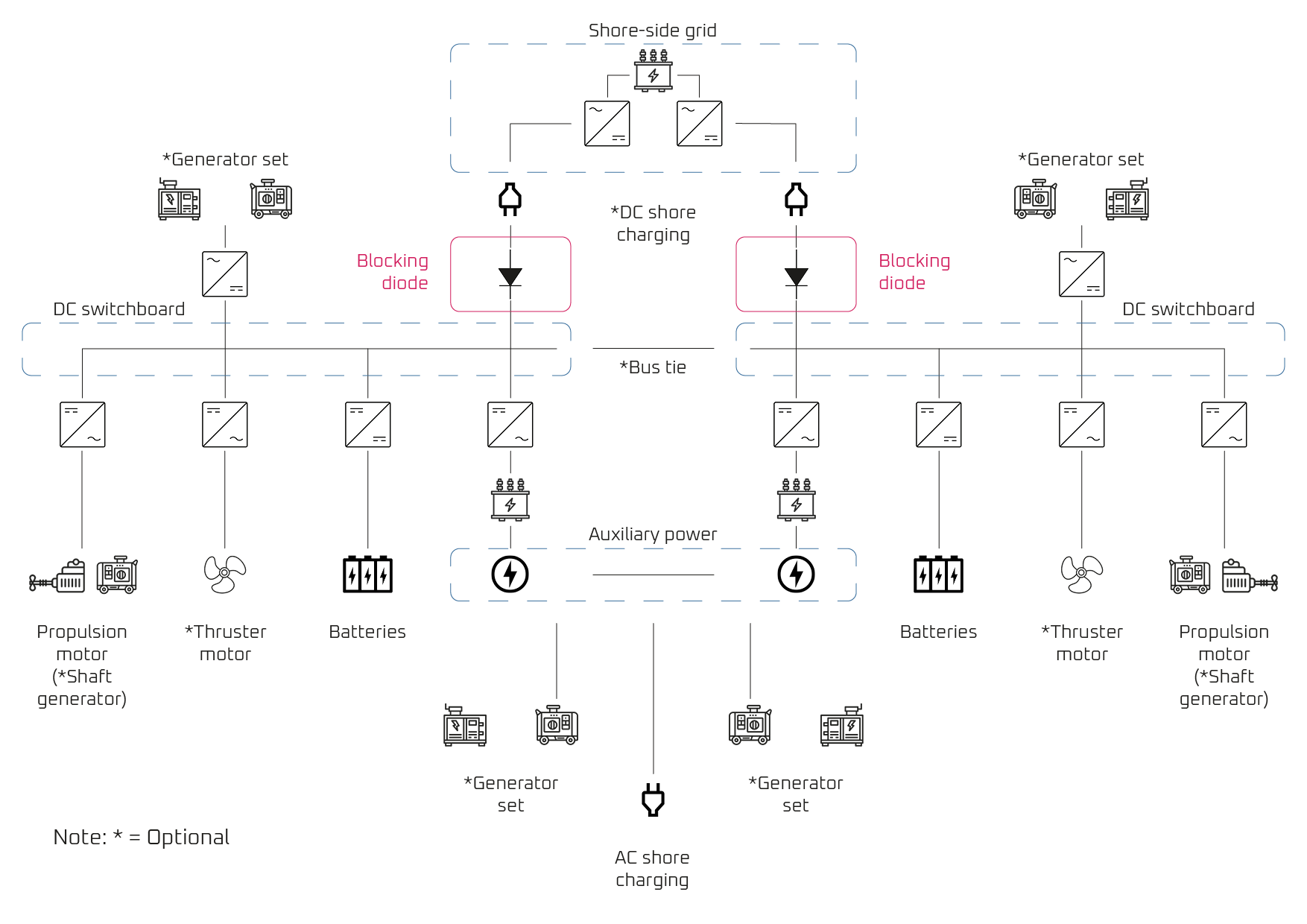

Preventing dangerous short-circuit situations caused by reverse current flow when charging electric vessels by using blocking diodes

In recent years, the shipping industry has witnessed tremendous transformation thanks to the ever stricter regulations imposed by the International Maritime Organization (IMO). Decarbonization is a growing issue and electric propulsion systems are being considered as potential solutions to meet this requirement. Most of the focus has been towards shipping electrification and the transition to DC and moving away from the traditional AC distribution system. Shipping electrification is still many years behind the electric vehicle (EV) or e-mobility transition, simply due to the fact that ships have larger systems which require higher amount of energy and power compared to cars. While Li-ion batteries are very efficient at powering vehicles, they are not as effective when it comes to powering most commercial ships. Despite the setbacks, there are indications that the marine industry is making steady progress thanks to the technological evolution of power electronics components. An example are the blocking diodes by Littelfuse which prevent short-circuit situations caused by reverse current flow when charging electric vessels.

“Power electronics components play a key role in shipping electrification when they are placed in a strategic location to achieve system selectivity and system safety.”

Recent trends in the use of alternative energies to replace fossil energy have increased the demand for power electronic components to connect these energy sources to the onboard DC grid. Each power electronics component plays a key role in shipping electrification when they are placed in a strategic location to achieve system selectivity and system safety as seen from the example below.

Protection with blocking diodes during shore charging

In our business, we often see specifications for a battery charging system that includes a requirement for a ‘blocking diode’. Sometimes, customers know exactly what they want for their system but most of the times the requirement is very fuzzy, with description like ‘The charger must not discharge the battery during a power failure’ which often translates to requiring a blocking diode. The exact function of the blocking diode is to protect the system from dangerous situations like arc flashing that might occur during the charging phase. Last but not least, component failure and consequential damages are prevented which adds up to a significant amount of cost savings. This is achieved by adding a diode module that prevents the current from flowing in the opposite direction.

What is a blocking diode?

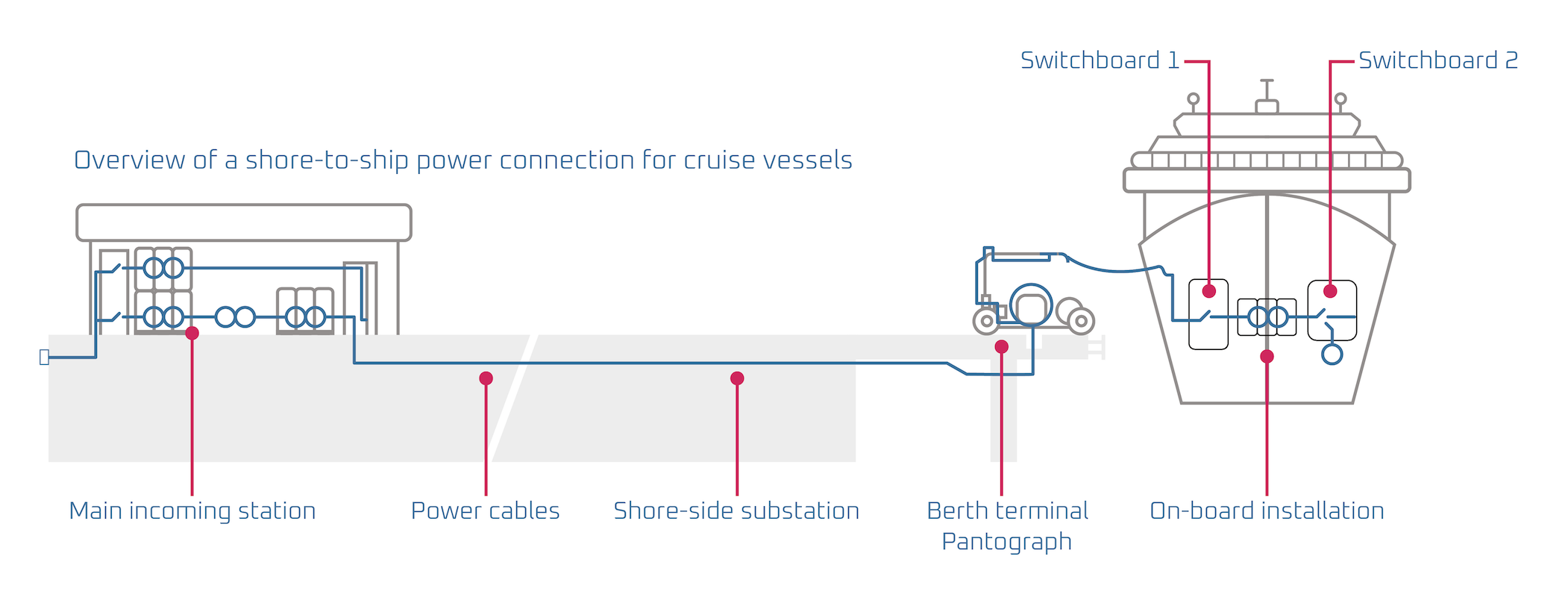

A blocking diode allows the current to flow from inverter system to the battery but prevents / blocks the flow of current to the inverter system thereby preventing the battery from discharging due to reverse current. Blocking diodes are also used for protecting and preventing dangerous situations caused due to arc flashing. In our business, we often see some problems that occur during the onshore charging phase. For example, there is a charging station on shore that provides power to a pantograph which in turn provides an electrical connection to the vessel. The vessel side of the pantograph distributes the power to 2 switchboards. In these switchboards, blocking diodes can be used to prevent the feeding of short circuit current from the ship installation back to the shore supply.

What is Reverse Current?

How to block reverse current in electric vessels with blocking diodes?

Reverse current can damage internal circuits and power supplies such as batteries. Depending on the path from output to input, reverse current can damage cables and connectors. If the heat, developed by power dissipation over the device surpasses the thermal rating of the device, it may result in combustion. Therefore, it is important to control the reverse current flow.

“A perfect blocking diode protects human & system”

A blocking diode can be very effective with its high voltage, high current application and it can be easily integrated in the existing system. Blocking diodes come with different specifications for reverse current protection, making them a good fit for a wide range of applications. A perfect blocking diode consumes power but protects human & system. In addition to costs, in all cases there is mounting consideration and above all, additional space in the housing where it is placed. This problem can be overcome by making the right choice of size, power rating and cooling type. Astrolkwx’s power electronics and semiconductor specialists are here to advice you!

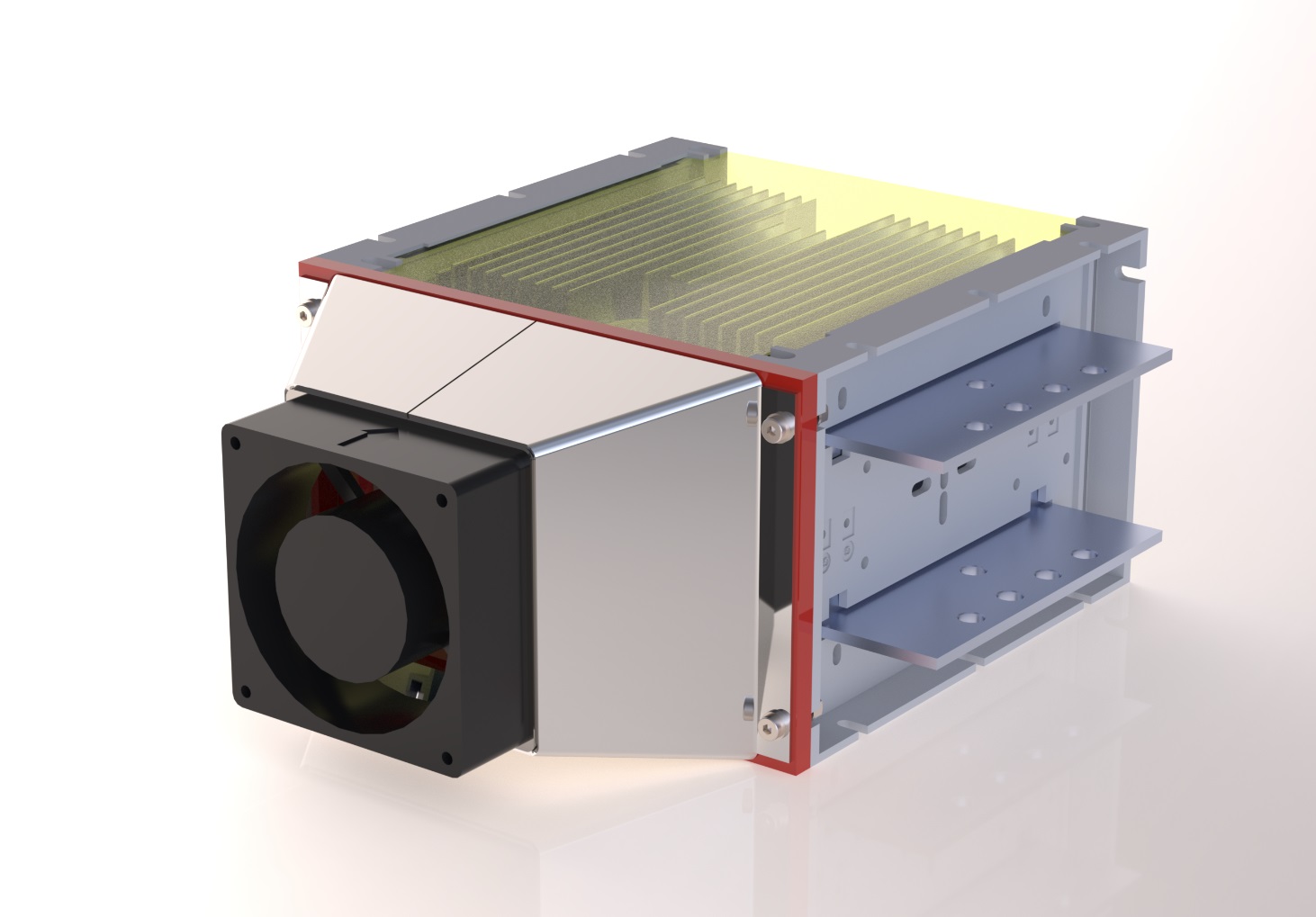

Customer example: existing air cooled system

One of our customers needed a blocking diode to block the current from opposite direction. one for positive and one for negative pole. They had an extremely limited space in the existing standard 600 mm wide cabinet and therefore, forced air cooled option for this with 1000V and 2000A application was the only solution. The fan provided forced air cooling with suction at the bottom and pushed it out at the top. Since liquid (water) cooling requires less space than air cooling, it is preferred for applications with limited space. For newly built ships, there is a lot of freedom for system design and hence liquid cooling is the obvious choice. However, in this case there was no cooling water supply available and a very low on-state loss diode from our valued supplier Littelfuse (former Westcode) did the job. Littelfuse blocking diodes prevent short-circuit situations caused by reverse current flow when charging electric vessels

Blocking diode for electric vessels / marine applications

The disk diode is placed and mounted between two heatsinks, a fan is placed on top, weherby the heatsinks are forced air or liquid-cooled. The design is customer specific.

Specifications

- I(load): 500 – 2000 A

- Vdc = 1000 V

- Ta =< 30°C

- Tj =< 160°C

*Other ratings and circuit configurations are available

Interested in the advantages of this technology to your marine projects?

Would you like to know more about the possibilities of preventing reverse current flow by applying blocking diodes? You can contact me directly using the button below, or leave your details in our contact form.